Fabless Manufacturing Applied to Optics

Fabless manufacturing is common nowadays in the semiconductor industry with the likes of Qualcomm, NVIDIA and Apple being well known proponents. These are companies who concentrate on design and marketing of their products but don’t take any part in the fabrication of the product. Fabless manufacturing started in the 80s in Silicon Valley (a relative stone’s throw from Selene’s head office). Prior to then chip fabrication was done through conventional vertically integrated companies. The reason for the shift was two-fold; the capital investment to set up a fab was huge, and there was excess capacity in some fabs. In recent decades fabless companies have also benefitted from engaging with manufacturers in lower labor cost parts of the world.

The term “fabless” hasn’t been widely used in other industries although there is now talk of automakers manufacturing this way1,2.

The optics industry could be a special case for fabless manufacturing. In most industries there is a pretty standard way of manufacturing the product. In optics, while necessary design skills are similar for most products the manufacturing requirements can vary widely. Do you set up a factory for high precision, hand-built optics in low volume or for low-cost, high-volume plastic moldings? No one does both. Selene Development has an experienced team of optical designers who can design more or less any type of lens or optical system, from high NA microscope objectives to camera lenses to LED illuminators. To provide hardware we have adopted a fabless manufacturing approach and developed a series of manufacturing partners which have characteristics which match a wide range of products.

Consider four types of optics applications: space, laser micromachining, automotive optics like ADAS or lidar, and low-cost plastic optics. Similar arguments apply to military, life sciences, medical etc. but let’s stick to these as examples.

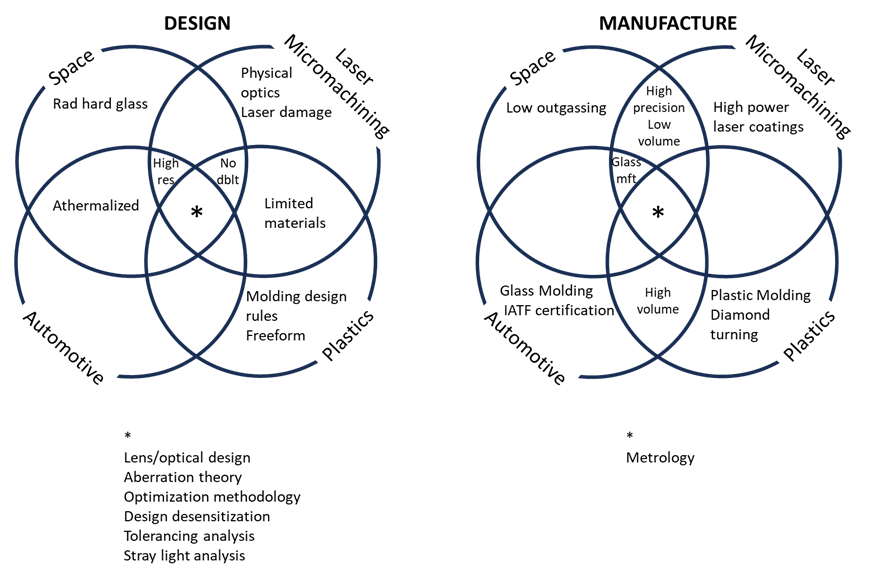

If you look at the design and manufacturing requirements shown on the Ven diagrams above, you see that a fabless approach with carefully selected manufacturing partners works well for an optics company. The fundamental design skills shown by the asterisk overlap all applications. Add to that some specific knowledge like the design of freeform optics and design rules of molding and you can provide designs for plastic lenses. If you can design a lens for space applications you can design an automotive lens, since they are both high performance, athermalized lenses. With experience of physical optics propagation and laser damage thresholds you can apply your skills to high power laser optics.

The manufacturing of these lenses, however, requires completely different manufacturing set ups. Automotive manufacturing is always high volume and very cost sensitive and will require appropriate factory certification. Lenses for space applications will be made in a single figure manufacturing run. A plastic lens provider will have invested in diamond turning tools and will have molding expertise. All the lenses could probably utilize the same MTF test equipment and most lenses will be polished on similar tools but that is about the limit of the overlap.

To meet these challenges Selene Development has been building (and continues to build) close relationships with a select group of manufacturers, leaving us to concentrate on the design and customer interface. Let’s be clear, these are not simply suppliers. Suppliers are companies we send specifications to and receive a quote for the item like a filter, say. The interface in this case is with the sales team. Our partners are companies in which we are heavily integrated. We are in contact with the manufacturing technical team, we get feedback on how we should modify mechanical detail to help production or to change a glass type. We know their manufacturing tolerance capabilities, and exactly what tools and metrology they have. We know their polishing surface roughness, we have their coating designs and the as-built coating performance, all of which feeds back into our stray light analysis. We treat our partners as companies would with their own factory, and we are able to do it across the spectrum of applications. It takes time and trust to develop these relationships, but the investment is worth it.

You don’t have to be as big as Qualcomm to go fabless!